MBP Medical Biomaterial Products GmbH Medical devices according to DIN EN ISO 13485 since 1995

Specialized in the production and approval of class III medical devices made from porcine collagen

For us, quality comes first, and you can see it in every detail. We use state-of-the-art equipment to extract collagen from animal materials. Our production is equipped with two state-of-the-art freeze-drying systems that ensure the highest precision and efficiency. In two class C clean rooms, we create the perfect environment for our manufacturing processes. Cleanliness and sterility are not a matter of compromise here, but a top priority. Our own sterile packaging line completes the picture. Here, we ensure that each product is packaged with the utmost care to preserve its quality and efficacy.

At MBP, we know that excellent products are based on excellent foundations. That is why we rely on close and trusting cooperation with highly qualified suppliers. Our carefully selected partners share our high quality standards and provide us with the foundations for our first-class products. Together, we create the basis for reliability and consistency in medical device manufacturing.

At MBP GmbH, we firmly believe that customer satisfaction is the key to our success. Our customers deserve nothing less than absolute excellence in products and service. Their satisfaction is our benchmark for quality and innovation.

We focus on diversity and flexibility to ensure that our products get into the hands of those who need them. That’s why we not only operate our own sales force, but also rely on proven distribution partners. Our own sales force guarantees direct access to our products as well as excellent service and support. Our hybrid distribution model allows us to respond flexibly to the different requirements of our customers.

With MBP GmbH you can count on proven reliability and first-class quality. Put your trust in our expertise.

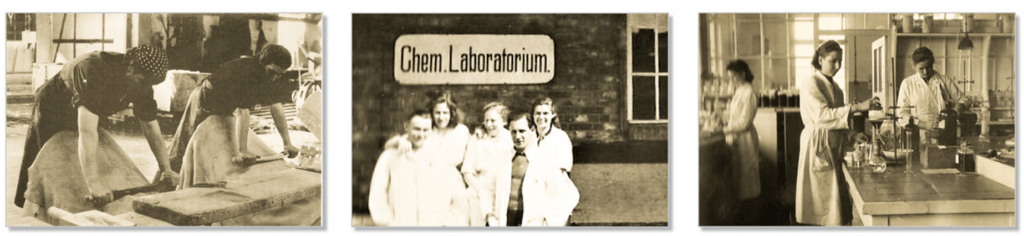

MBP – Medical Biomaterial Products GmbH is a successor company of the pharmaceutical production division of VEB Lederwerk Neustadt-Glewe.

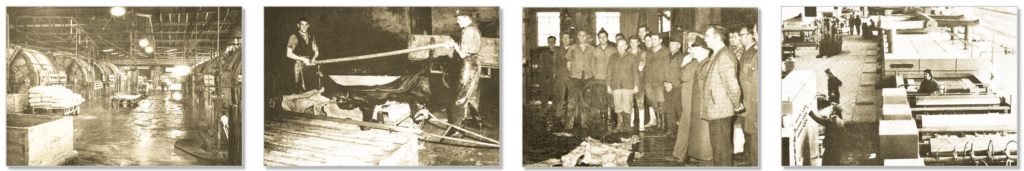

The original factory was built in 1911 by the company “Adler and Oppenheimer”. After the foundation of VEB Lederwerk “August Apfelbaum”, the company developed into the leading manufacturer of pig leather in Europe at the end of the 1970s.

The decisive breakthrough in the market for medical products came on November 25, 1980, when the company began manufacturing “XENODERM,” a sterile wound dressing for covering burns. In 1984, the portfolio was expanded to include the collagen fleeces Surgicoll and MB-Collagen, which have been available on the market as approved medical products since 1986.

After the plant was closed in 1994, its pharmaceutical division was taken over by MBP GmbH and built on the previous research.

- Founded in 1911 as a new production facility of the company “Adler and Oppenheimer” (Strasbourg)

- From 1956 continuation as pharmaceutical production division of VEB Lederwerk Neustadt-Glewe

- At the end of the 1970s, Lederwerke was the largest pigskin processing plant in Europe with business connections on three continents

- 1980 Refinement of pig skin into a sterile wound dressing to cover burns (Xenoderm).

- From 1984 production of collagen fleece for hemostasis as a pharmaceutical product

- 1994 Foundation of MBP – Medical Biomaterial Products GmbH as successor company of the leather factory August Apfelbaum

- From 1994, focus on the production of collagen hemostyptics and Xenoderm from porcine skin, as well as on the development of new medical products under the leadership of Managing Director Dr. Barat Behjati

- Since 1996 certification as manufacturer of medical devices according to DIN EN ISO 13485

- 2008 Modernization of clean room production

- 2011 new management

- 2011 Opening of the companyextension and creation of a larger warehouse and new offices.

- 2013 Opening of an additional clean room and significant increase in clean room capacities.

- 2018 Opening of the next building expansion, investments in acquisition and qualification in clean room technology, packaging machines and personnel to increase production capacities.

- 2018/2019 Qualification as a supplier of medical devices in Australia, Brazil and the USA, among other countries

- 2023 Certification of Xenoderm, MB-Collagen, Surgicoll and Diacoll as class medical devices under Medical Device Regulation 2017/745 (MDR).

Order processing, supplier management, invoicing

Contact person: Nicole Gieseler

Research and development

Contact person: Axel Kob

Head of production

Contact person: Viola Manteufel

Quality assurance

Contact person: Nadine Kruse

Sales, Quality Management, Regulatory Affairs

Contact Person: Josephine von Olleschik

Address for digital invoicing:

Trust in controlled quality! Our company is certified according to DIN EN ISO 13485:2021

Choose a trusted partner who sets the highest standards in the medical device industry. Together we create reliability and quality!

In order to continuously improve our products, we proactively integrate suggestions from customers, market feedback as well as internal company suggestions to constantly optimize the quality of our products. Our quality policy is designed to produce products and services of the highest quality in order to gain and maintain the trust and satisfaction of our customers and to ensure patient safety.

- Absolute commitment to quality: Our company is committed to setting the highest standards in medical device development, manufacturing and delivery.

- Safety through regulatory compliance: We meet all legal and regulatory requirements to ensure the safety and efficacy of our products.

- Professional risk management: We rely on structured risk management to continuously improve the safety of our medical devices.

- Efficiency and continuous improvement: Our focus is on efficient processes and continuous improvement to enhance the quality of our products.

- Customer focus: Your satisfaction is our ultimate goal. We listen and improve based on your feedback.

- Our medical devices meet the strict requirements of the Medical Device Regulation (MDR) for Class III devices.

In our close collaboration with other companies and renowned universities, we are pioneers in the research and development of collagen-based medical products. Together, we implement groundbreaking projects to shape the next generation of products to market maturity. Our special expertise lies in the refinement of your products with the help of high-quality porcine collagen.

But that’s not all – we also offer comprehensive regulatory support to ensure your products meet the highest quality and safety standards. Through this unique partnership, we enable you to push the boundaries of possibility and help shape the future of the medical device industry. Trust us as your reliable partner on the path to innovative solutions!

In addition to our own products, we also manufacture for third parties and develop innovative products together with our partners. We are proud to also manufacture for external customers and work together with our partners to develop groundbreaking medical solutions. This partnership approach enables us to drive innovation and further improve medical care.

At MBP, we open doors to exciting opportunities. We are looking for committed and ambitious partners who want to conquer the world together with us.

Why a partnership with us?

Innovative products: We offer first-class products based on the highest quality standards. This gives you a solid foundation for your success.

Comprehensive support: As a sales partner, you will have access to our expertise and marketing materials We will provide you with advice and support.

Attractive conditions: Fairness and transparency are our top priorities. We offer attractive conditions that promote your success.